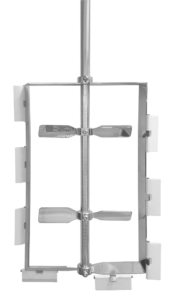

Spiral Stirrer

International Cleanroom Quality

For even the most demanding environments in the Pharmaceutical, Cosmetics, Food and Chemical industries

Key Benefits:

- Ideal for gentle stirring of medium to high viscosity products and products that are very delicate.

- 3 bladed spiral stirrer for homogenous mixing and aiding heat transfer.

- Durable, easy to sterilise and re-useable, for long service life and greater ROI.

- High level finishing - to an exceptional average surface finish of 0.4 µm Ra - leaves no pits or crevices for bacteria to store.

Product Information:

- Close tolerance stirrer to suit vessel shape and application, to ensure good mixing coverage.

- Low speed, low shear stirrer, typically 50-100rpm.

- Ideal for medium-high viscosity products (1,000-10,000 cP).

- Hygienic 316L stainless steel product contact parts.

Options:

-

- Sizes to suit customer’s application

- Motor to suit customer application

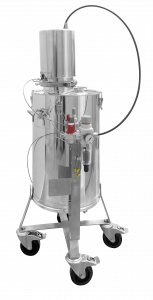

- Integration into Pharma Hygiene Products mixing vessel system

Pharma Hygiene Products also offers a High Shear Mixer, ideal for mixing water-to-oil, to form a light emulsion, and a Propeller Mixer, for mixing liquid-to-liquid, oil-to-oil, and free dissolving powder into liquid.

How Do I Maintain A Spiral Stirrer?

In order to get the best useful life out of your spiral stirrer, correct maintenance should be completed. Please find below some tips on how to maintain this:

- Clean immediately after use.

- Ensure that the spiral hook and the dough breaker bar need to be prioritised when cleaning, especially if you have been working at a high temperature.

- Clean the cover & the grid too.

What Is A Spiral Stirrer?

A spiral stirrer is used to prepare bread dough (or similar products) which replaces the labour through a system that enables he continuous production of large amounts of dough.

Chat with us!

Chat with us!