News Blog

Keep up to date with the latest news, insights and features from Pharma Hygiene Products

Aseptic Manufacturing: High Performance Mixing and Product Containers

December 13, 2023

Engineering for Aseptic Manufacturing

Aseptic manufacturing is a sophisticated and meticulously controlled process within the pharmaceutical industry, which aims to produce sterile products by preventing the introduction of microorganisms during the manufacturing process. The key objective is to maintain a sterile environment throughout the entire production cycle, from raw material handling to packaging.

This stringent approach involves the use of advanced technologies such as isolators, laminar airflow systems, and sterilization techniques to eliminate or control microbial contamination. Aseptic manufacturing is crucial for the production of injectable pharmaceuticals, biologics, and sterile medical devices, where even the smallest microbial presence can compromise product safety and efficacy.

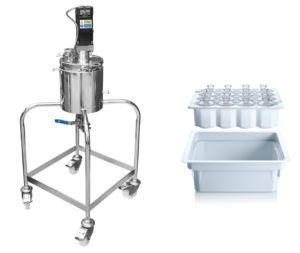

Examples of bespoke Aseptic Mixing Solutions by Adelphi Pharma Hygiene Products include:

Example #1 – 5L Low Pressure Jacketed Vessel

Application:

Manufacturing medicines in a research laboratory; the customer needed a vessel to act as a ‘break tank’ between their larger batches of product in drums, and their delicate vial filling system.

Features:

A sensor ensures that the product volume never falls below a certain level, so the filling machine is kept consistently fed with product. The mobile frame makes cleaning the vessel quicker, as it can be moved away from production to cleaning and back, as and when it is required.

Results:

The low pressure (1 bar of working pressure) perfect matches the laboratory heater/chiller unit which the vessel is connected to. A minimum of 80L per day of product is now successfully running through.

Example #2 – 200L Mixing Vessel

Application:

Mixing water for injection with free-dissolving powders, for a manufacturing hospital.

Features:

The motorised mixer consistently mixes the correct ratio of water to powder, which is not able to be achieved manually, in batch sizes this large.

Results:

Guaranteeing the highest standards of hygiene is critical when manufacturing injectables. 316L pharmaceutical grade stainless steel construction – with an exceptional surface roughness level of 0.4 micrometers Ra – gives security that bacteria will not be stored, and allows the most thorough cleaning in the cleaning process. 800L of product is now mixed in 4 hours every morning, ready to be filled in the afternoon.

Do you have a query about mixing for your aseptic manufacturing project?

Simply email info@pharmahygieneproducts.com – our dedicated team will be delighted to assist you.

After mixing and prior to filling, the product is typically subjected to biological filtering to 0.25µm, before being filled into vials or syringes…..

Vials & Syringes – Premium Primary Packaging from Adelphi Healthcare Packaging:

Adelphi Pharma Hygiene Products is proud to be part of the Adelphi Group of Companies. Although our Group began life in 1947 as Adelphi Manufacturing Limited, today we are a group of four complementary divisions. They combine to offer the most comprehensive support possible to our customers. We are therefore delighted to introduce you to our sister company – Adelphi Healthcare Packaging – who supply ISO standard vials, syringes and other pharmaceutical containers and closure systems, manufactured by market-leading names, including SCHOTT and West.

Their offering includes sterile RTU components and high-spec internally coated vials, designed to solve a multitude of processing and formulation challenges. Minimum order quantities start from just a single pack, ready to be shipped globally straight from stock.

Do you have an enquiry about suitable primary packaging for your aseptic manufacturing project?

Simply email info@pharmahygieneproducts.com – we would be very pleased to connect you with the relevant member of the Adelphi Healthcare Packaging team.

Chat with us!

Chat with us!