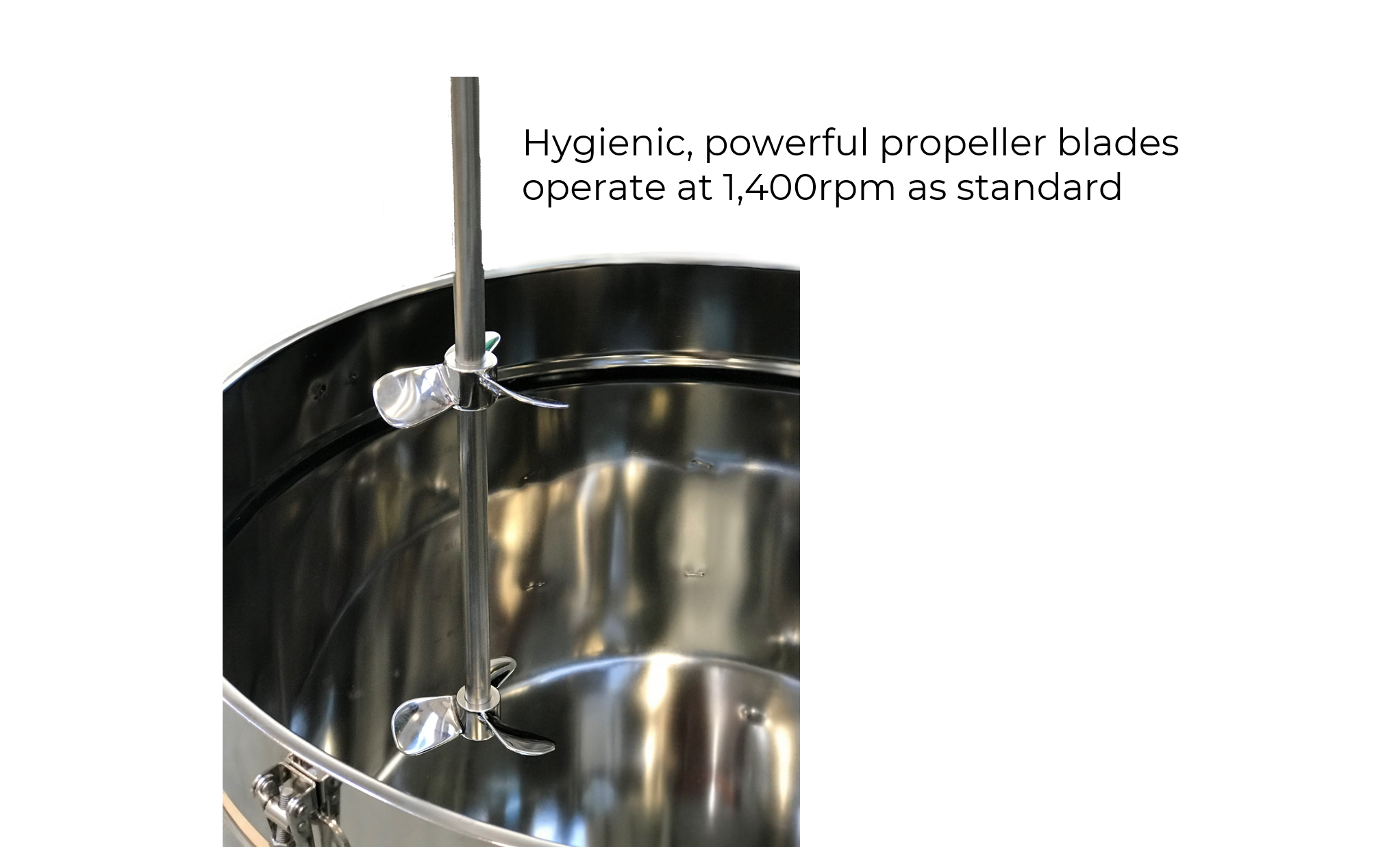

Propeller Mixer

International Cleanroom Quality

For even the most demanding environments in the Pharmaceutical, Cosmetics, Food and Chemical industries

Key Benefits:

- Ideal for mixing liquid-to-liquid, oil-to-oil, and free dissolving powder into liquid.

- 304 grade stainless steel, with 316L pharmaceutical grade wetted parts, to guarantee no product contamination.

- Durable, easy to sterilise and re-useable, for long service life and greater ROI.

- High level finishing - to an exceptional average surface finish of 0.4 micrometers Ra - leaves no pits or crevices for bacteria to store.

- Full material traceability for international pharma-quality compliance: Material Grade, Surface Finish & TSE certification available upon request.

Product Information:

- As standard this unit operates at 1,400rpm.

- Suitable for products with a viscosity up to 2,000cP (mPas).

- Batch sizes from 20L upwards (maximum diameter of base vessel 800mm).

- 0.37 kW (up to 100L batch size) or 0.75 kW (up to 300L batch size) mixer options, dependent on batch size and viscosity.

- Options:

- Variable speed

- 3 phase or single phase

- 0.37kW

- 0.75kW - Can be supplied with a mobile frame for mobility.

Pharma Hygiene Products also offers a High Shear Mixer, ideal for mixing water-to-oil, to form a light emulsion.

Pricing:

| Product No. | Description | Material | Price |

|---|---|---|---|

| CSP031-201 | Mobile Stand with 0.375 KW Propeller Mixer | 304 SS | £6510 |

| CSP031-501 | Mobile Stand with 0.75 KW Propeller Mixer | 304 SS | £6825 |

What is a Propeller Mixer?

Typically three-blade in design but sometimes incorporating a fourth, a rotating propeller is mounted to your vessel off-centre and at a slight angle to improve mixing. This is most often used for mixing free dissolving powders into water.

The process creates a vortex – the operator adds the powder into the vortex, which then passes through the propeller. The vast majority of the mixing is achieved in the first pass through the propeller mixer. This is therefore an extremely time-efficient process, which is also ideal to prevent clumping from occurring.

Subsequently your mix recirculates around the mixing vessel vertically: the product travels down through the propeller, then up the side of the vessel, and then back down into the propeller again.

Common applications of Propeller Mixing are for manufacturing Vitamin mixes, Tablet coatings or Medicines, although these versatile solutions are also commonly found intermediate stages of food production too.

Propeller Mixers can also be used to mix oil into oil, and liquid into liquids, that aren’t at risk of separating out like oil and water would.

Contact us today to discuss your mixing requirements with a member of our experienced technical team.

What Is A Propeller Mixer Used For?

A propeller mixer is used for mixing liquids and dissolving solids within liquids. They are known for their long lifespan and strong stability.

Chat with us!

Chat with us!