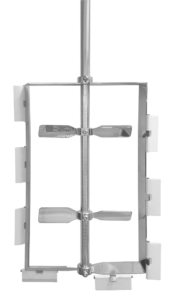

ATEX Certified Mixing Containers

International Cleanroom Quality

For even the most demanding environments in the Pharmaceutical, Cosmetics, Food and Chemical industries

Key Benefits:

- Take advantage of our 70+ years' experience; we can advise the most cost-effective solution for your business.

- Durable, easy to sterilise and re-useable, for long service life and greater ROI.

- High level finishing - to an exceptional average surface finish of 0.4 micrometers Ra - leaves no pits or crevices for bacteria to store.

- Full material traceability for international pharma-quality compliance: Material Grade, Surface Finish & TSE certification available upon request.

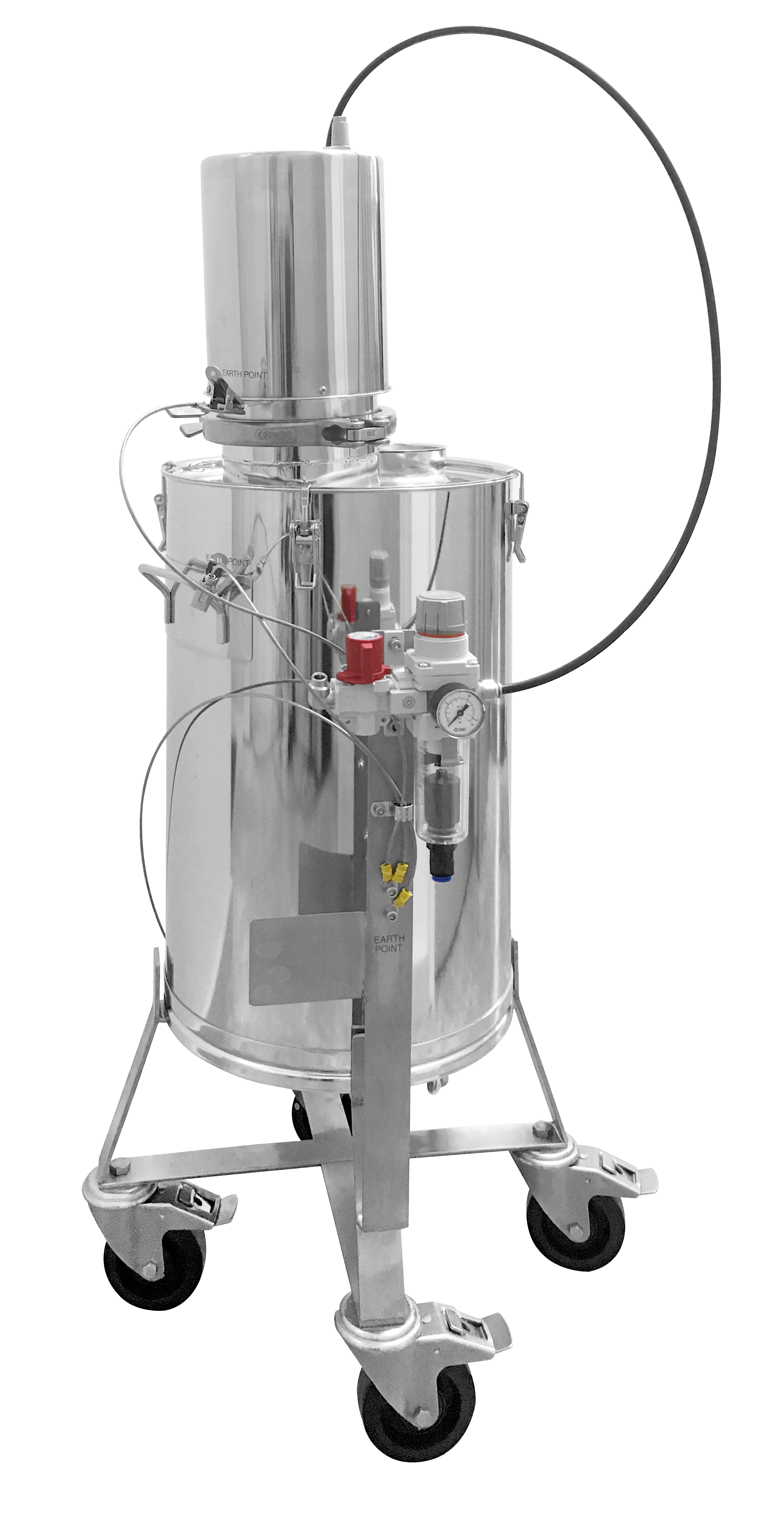

Product Information:

- CAT IIB 2DGc T4 (135 degrees Celsius) equipment.

- Air Motor Mixer suitable for use in category 2 & 3 areas (Zone 1 & Zone 2).

- For vapour mixtures with ignition energy of either A or B, and with auto-ignition temperatures suitable for 135 degrees Celsius or higher.

- Compliance peace of mind: appropriate technical files are lodged with an approved body.

- 304 or 316L pharmaceutical grade stainless steel.

- Solutions from 25L to 400L.

Pharma Hygiene Products also offer:

What is an ATEX Compliant Mixing Vessel?

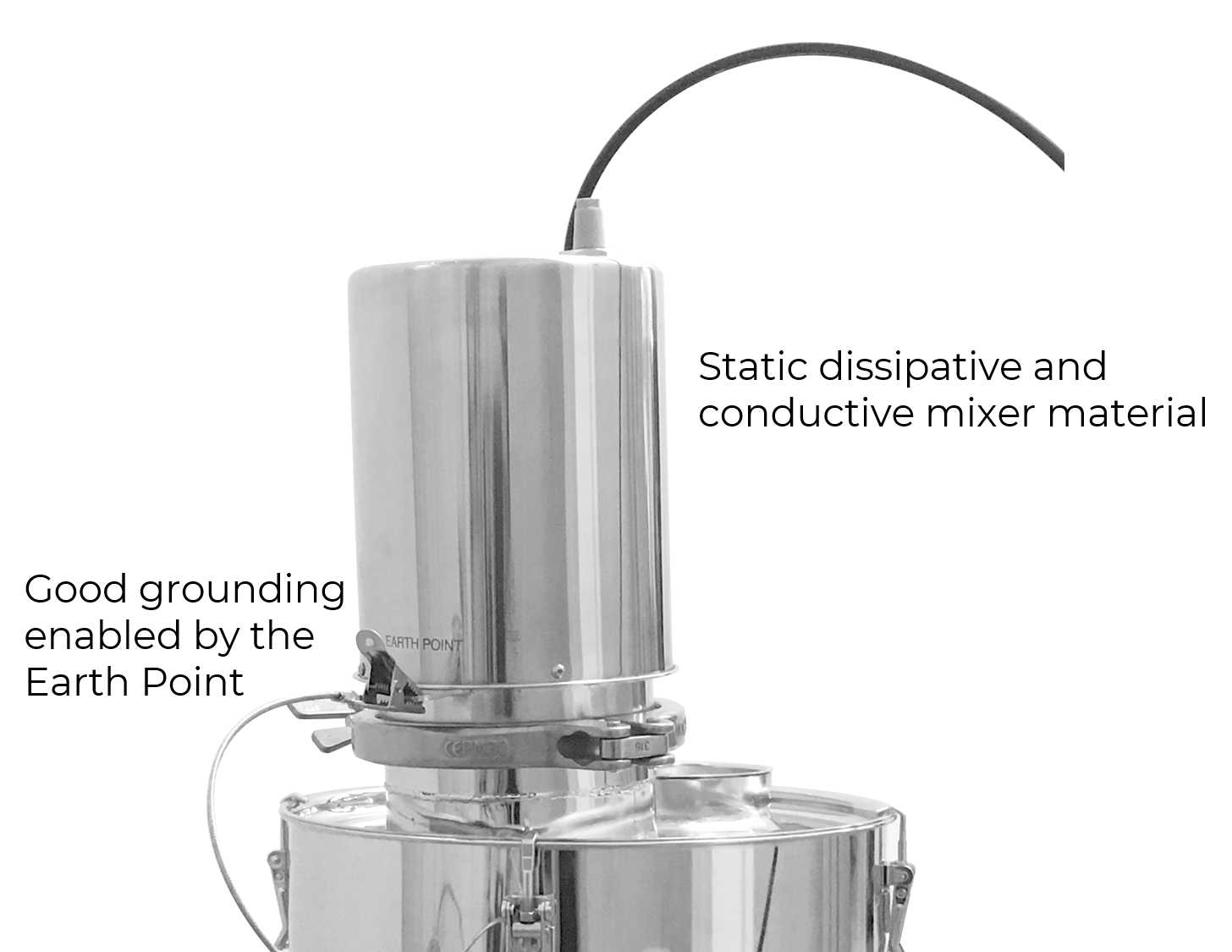

ATEX certification is required when mixing high-ethanol content products, or those with potentially flammable ingredients – to ensure no static can build up and spark during the mixing process, which eliminates the risk of an explosion.

ATEX compliance is achieved by – amongst other aspects – excluding any electrics in our designs. We use air motors instead of electric motors, and speed control is via a pressure regulator.

ATEX compliant mixing vessels control the risk from potentially flammable Gasses – for example, vapours given off by a solvent which mix with oxygen in the air, or Dusts – such as flour, chemical dusts or metal powders.

Which Applications Required ATEX Compliant Mixing?

Pharmaceutical applications including tablet coatings usually incorporate ethanol, which is mixed with a powder – then the ethanol evaporates leaving the powder behind. Other applications we have previously created vessels for include Medicated confectionery, Animal tranquilizer, Epoxies, Resins and other coatings – Perfumes, Cleansers and Toners often incorporate ethanol, as do Hand sanitizers.

Chemicals and agrochemical applications frequently require ATEX compliant mixing processes, including companies manufacturing household cleaners, white spirit and other cleaners.

Food and beverage manufacturers use ATEX compliant vessels to blend high ethanol-content products such as flavoured spirits and cocktails.

Contact our expert team today for further information about ATEX certified mixing.

Contact us about this product

Case Studies

Medicated Confectionery

Maximised production space and output for medicated confectionery manufacturer

Chat with us!

Chat with us!