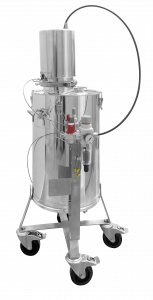

Jacketed Mixing Containers

International Cleanroom Quality

For even the most demanding environments in the Pharmaceutical, Cosmetics, Food and Chemical industries

Key Benefits:

- Ideal for heating, cooling or maintaining a consistent product temperature whilst mixing.

- Take advantage of our 70+ years' experience; we can advise the most cost-effective solution for your business.

- Durable, easy to sterilise and re-useable, for long service life and greater ROI.

- High level finishing - to an exceptional average surface finish of 0.4 micrometers Ra - leaves no pits or crevices for bacteria to store.

- Full material traceability for international pharma-quality compliance: Material Grade, Surface Finish & TSE certification available upon request.

Product Information:

- 316L pharmaceutical grade stainless steel, with a 304 grade water jacket.

- Solutions from 0.3L to 2,500L.

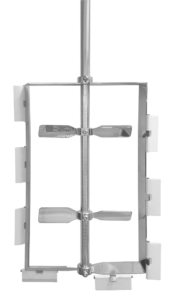

- Options include:

- Heated, cooled or insulated jackets

- Flat, flat sloping, cone or dished container bottom

- High shear, propeller or agitator mixing solutions of varying power and speed

- Low pressure jacket for temperature control

- Insulation jacket for health and safety compliance above 65°C

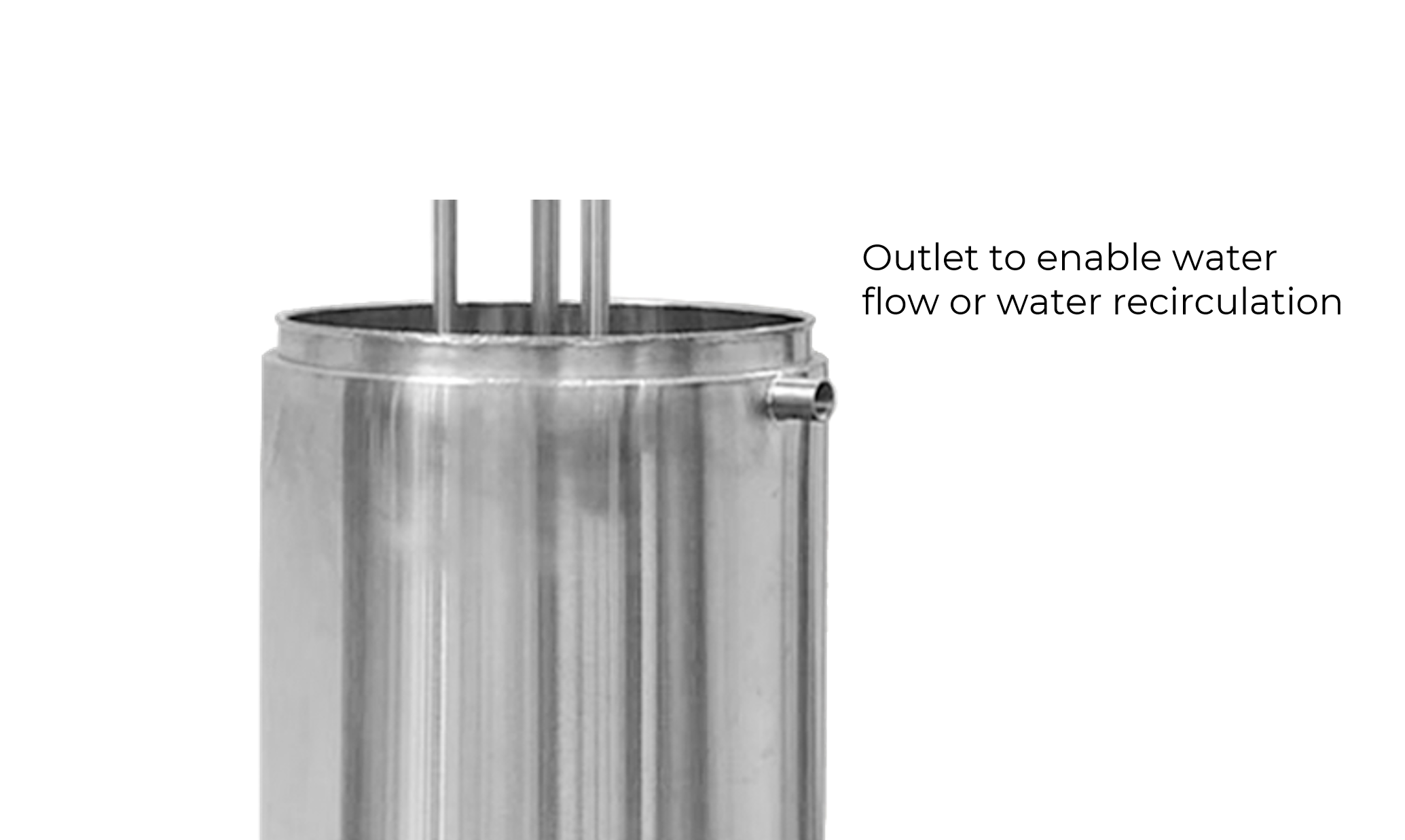

- Recirculating temperature control unit or vented immersion heater.

Pharma Hygiene Products also offers:

Lids, airtight toggle clamps and seals, mobile frames and outlets for decanting are also available for all mixing containers, along with a range of other optional modifications to meet every requirement.

What is a Water Jacketed Mixing Vessel?

A vessel where control over temperature is required – either heating, cooling or both. When heating to temperatures up to 65°C, it is not necessary to insulate the vessel, but above this you will require an insulation layer. In essence, the insulation layer is another jacket, with air in it to prevent extremely hot surfaces.

In some instances, it may be necessary to insulate if you are cooling, to ensure you don’t lose so much energy.

Temperature control can be achieved in different ways depending on your application:

- Immersion heaters – for heating only

- Temperature control units (TCU) – ideal for applications requiring both heating and cooling, or those who require a more precise degree of temperature control

Which Applications Require a Water Jacketed Mixing Container?

Many food products need to maintain a high temperature for pasteurisation; above 85-90°C generally.

Products such as jams also require heating during the production process, as if they are left to cool they can become unmanageable in later production stages such as filling. This also applies to cosmetic products which utilise wax as an ingredient, such as skincare creams or balms.

In the pharmaceutical industry, some ingredients only activate at higher temperatures.

To discuss your mixing requirements in more detail, you are very welcome to contact our technical team, who will be delighted to assist you.

Contact us about this product

Case Studies

Nelsons Spatone

Bespoke solution removes the need for holding-tanks, increasing productivity for Nelsons Spatone

E-Liquid

Hygienic, certified quality mobile vessel gives international E-Liquid manufacturer’s production complete security

Chat with us!

Chat with us!