Gate Stirrer

International Cleanroom Quality

For even the most demanding environments in the Pharmaceutical, Cosmetics, Food and Chemical industries

Key Benefits:

- Ideal for slowly stirring medium to high viscosity products, including creams, pastes and thick sauces.

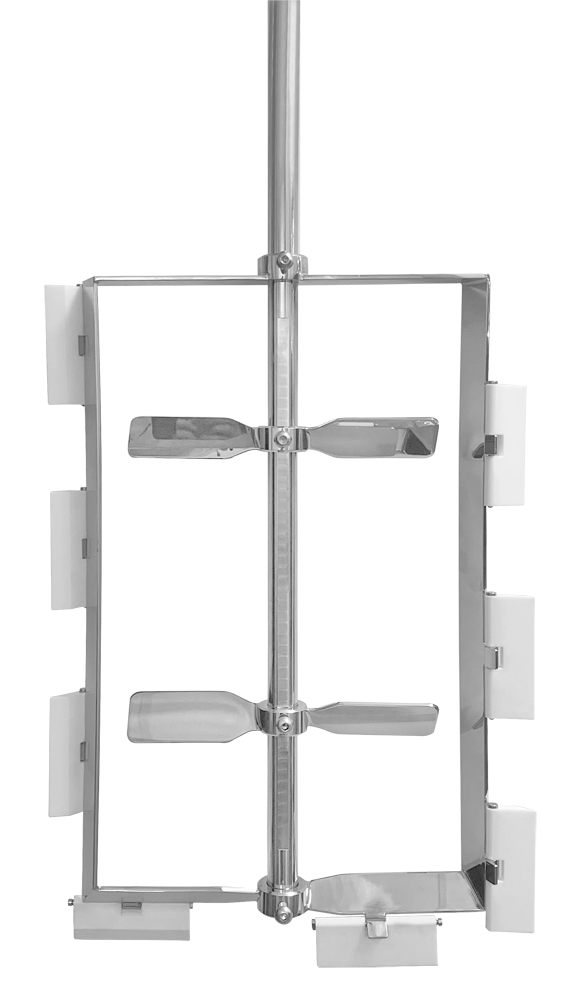

- Central propellers enable thorough mixing, and the design can also include pivoted wall scrapers for products that are susceptible to burning/adhering to the vessel wall. The scrapers introduce the product back into the mix to also aid heat transfer, if needed.

- Durable, easy to sterilise and re-useable, for long service life and greater ROI.

- High level finishing - to an exceptional average surface finish of 0.4 micrometers Ra - leaves no pits or crevices for bacteria to store.

Product Information:

- Close tolerance stirrer to suit vessel shape and application, to ensure good mixing coverage.

- Low speed, low shear stirrer, typically 50-100rpm.

- For use with high viscosity products (10,000-100,000 cP).

- Hygienic 316L stainless steel product contact parts.

Options:

-

- Pivoted PTFE wall scrapers to clean vessel walls or aid heat transfer

- Height adjustable central mixing blades

- Motor to suit customer application

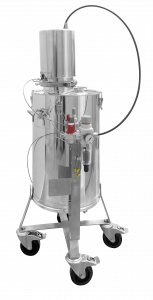

- Integration into Pharma Hygiene Products mixing vessel system

Pharma Hygiene Products also offers a High Shear Mixer, ideal for mixing water-to-oil, to form a light emulsion, and a Propeller Mixer, for mixing liquid-to-liquid, oil-to-oil, and free dissolving powder into liquid.

What is a Gate Stirrer?

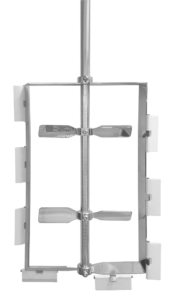

A gate stirrer is a generic term for a flat stirrer that resembles a gate in structure. It can be designed to look a variety of ways depending on the product being mixed.

The simplest version of a gate stirrer is a flat gate shape which follows relatively closely to the vessel wall, and rotates slowly to stir medium to high viscosity products.

The more complex iteration of a gate stirrer has central propellers to aid mixing, and also pivoted wall scrapers for products that burn/adhere to the vessel wall (as per the image above). The scrapers introduce the product back into the mix to also aid heat transfer, if needed, and reduce the amount of wasted product.

Contact our experienced technical team today, to discuss your mixing requirements and product characteristics in more detail.

How Long Do Gate Stirrers Last?

Gate stirrers have an expected lifespan from 10 – 20 years but can go beyond that if proper maintenance is in undertaken.

Chat with us!

Chat with us!